Smog & Emissions Testing

for your Porsche

I have been working exclusively on Porsche cars since the mid 80’s and got my first smog license in the early 90’s. Because of this I am constantly thinking about how daily maintenance, system functionality and emission controls all work together. This allows me to have a unique perspective into the Porsche emission control system as I have seen P-cars all the way from zero emission control all the way to Hybrid and electric models.

Below are some categories for you to choose from to navigate through information that more specifically outlines your smog & emission control issues and questions. There is a lot of information below but not all applies to one model; pick what applies to your specific Porsche and get informed.

1976 to 1979 Porsches (The no computer cars)

Smog Testing in California starts with 1976 model cars. 76-79 model year cars have no oxygen sensor or computer so all the magic must happen by adding too much fuel and then too much air. These engines generally have a 2-way catalytic converter, air injection and EGR. They run too much fuel (CO) to reduce NOx (See the NOx section above) and then inject fresh air into the exhaust to extend the burn to reduce the (CO) fuel mixture and (HC) hydrocarbons.

The two-way catalytic converter then further reduces CO and HC. This is a very primitive system but if all components are functional and everything is properly adjusted the car will almost certainly pas with flying colors. Most failures in these cars come down to worn out air injection systems, and incorrect timing and/or fuel adjustments or hose routing.

Be sure to also check out the catalytic converter care section!

Steve G’s Smog Tips:

- Make sure ignition timing is correct at idle as well as at testing speed around 2000RPM. An over advancing distributer will radically elevate NOx readings.

- A nonfunctional EGR valve will also increase NOx; if you have a NOx failure add vacuum to the EGR valve. The idle should drop if working properly.

- If there are two vacuum ports on the valve one makes a little difference, and one makes a big difference!

- Test tail pipe emissions with and without the air injection hooked up.

- Air injection (AIS) should make about a 50% reduction at idle speed, if not take a deeper look at it.

1980-1983 Porsches (3-way catalyst and Lambda control/oxygen sensor cars)

This second series of cars are vastly more efficient in fuel consumption and emissions than the previous versions. The advent of the oxygen sensor and 3-way catalytic converter was a serious game changer for emissions and performance. Before manufacturers really had to de-tune engines reduce emissions and now we could get some performance back while making even fewer exhaust emissions.

The magic of the lambda control system (The system that controls fuel mixture through the use of an oxygen sensor) is that it can instantly change the fuel mixture to suit our exact needs. As we are driving down the road to work, we are at a light load and want to get good gas mileage. The O2 sensor regulates the fuel mixture between the lean and rIch stop. The difference between these two points is 14.7:1 AFR or air fuel mixture. The lean stop lowers HC and CO levels but increases NOx levels. Then the rich stop increases CO levels which lower combustion temperature and greatly reduce NOx levels. This switch from rich to lean happens about once a second. The end result is low fuel consumption and lower overall tailpipe emissions than we could ever get without the use of a computer feedback system.

So now you are in a hurry and need to pass those 3 delivery trucks on that hill? Once you press the accelerator past 80% throttle a switch tells the computer you’re in a hurry and to leave it on the rich stop! This delivers more fuel for more power and better cylinder cooling and less detonation and most importantly more GO! All due to the magic of computers.

Because the lambda control system is so efficient, we got to lose the air injection and EGR systems of the previous version cars.

Steve G’s Smog Tips:

- Make sure ignition timing is correct at idle as well as at testing speed around 2000RPM.

- An over advancing distributer will radically elevate NOx readings.

- The second biggest cause of NOx on these cars when timing is correct is a bad oxygen sensor that is biased to the lean side and causes and overall lean fuel mixture. Check out oxygen sensor testing below.

1984-1989 cars

These cars are very trouble free and have very few problems when properly maintained. If your car fails, it is probably for NOx because the oxygen sensor didn’t get replaced when it should have (Before it failed) and it damaged the catalytic converter. Test the oxygen sensor as is outlined here and replace it if it is out of specification. Then add some catalytic converter cleaner and say a prayer that it comes back to life.

Chances are excellent that it will!

(See catalytic converter care above).

88-95 and OBD-I cars

These cars include all 964s, 1995 993s, as well as late 944 and 968 cars.

The beauty of these cars is they were light years ahead of their time with their onboard diagnostic system. Unfortunately, being OBD-I the systems are not standardized and you must have a specialized tester to read complete diagnostics and fault codes. However, you can get a 16 pin to 19 pin converter cable online and get many of the basic functions with the use of a cheap handheld OBD-II tester (See adapter picture below)

The emissions failure on this car is most likely going to be NOx. If you have a HC/CO failure that is more uncommon and needs a professional diagnostic. For NOx failure on 964/993 cars, you need to check the ignition. If the second distributer isn’t turning you found your problem! If not, then you probably have an oxygen sensor issue, see the 3-wire oxygen sensor section for testing.

96-98 Air cooled OBD-II cars

Come on, we all know what we’re talking about; 993 smog failure!

Air injection-

The most popular 993 smog failure is clogged AIS but that will be a check engine light issue, not a tailpipe emission issue. Air injection on these cars does not decrease emissions while the car is driving, only at start-up. It just adds additional air in front of the catalytic converters when the car is cold, so they heat up quickly and come online faster. So, failing air injection will not cause a tailpipe emissions failure even through it is bad for catalytic converter health.

If you have a 993 that has a fault code for bank one or bank two secondary air injection there are a few Band-Aid tricks to clean out the system but none of these are permanent repairs. You would be lucky to get through one test cycle with these repairs; what the car needs is top end disassembly and clean out of all the passages which usually leads to a top end engine overhaul.

High HC readings-

So, the cause of high HC readings is related to the air injection failure mode as well. The air injection system becomes clogged because the exhaust valve guides wear out and the car burns oil and creates carbon deposits in the air injection passages. That same failure mode causes oil burning and consumption that coats the exhaust including the catalytic converter substrates.

So, when these cars have high HC readings, and the oxygen sensors test well it is usually just a matter of running some catalytic converter cleaner through the system a few times to get your HC levels down within reason. The catalytic converter cleaner simply removes the oil deposits so the converter can increase efficiency. Many times you will need to replace at least the front oxygen sensors to help get the catalytic converters up to temperature before running the catalytic converter cleaner through the system.

See the section on catalytic converter care.

OBD-II monitors-

OBD-II monitors are a huge problem for 993 and later cars; see that section below.

97 and later water cooled OBD-II cars

These cars are generally very trouble free when it comes to passing their smog tests.

Air injection fault codes can exist, but they are usually caused by a bad vacuum line or vacuum switch. These are usually easily repaired and the code can be reset and you will be on your way. These cars can be difficult to pass monitors when there are no fault codes displayed and the car seems to be running perfectly.

See the OBD-II monitor section below for details!

Catalytic converter care

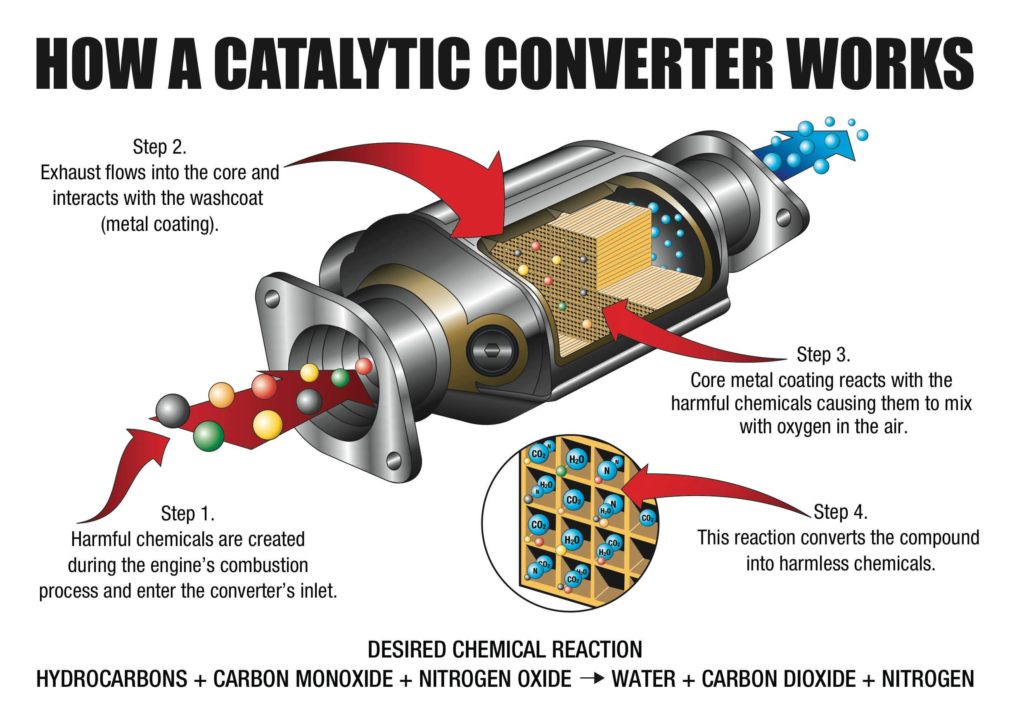

We have all heard the words “Catalytic Converter” and many of us could point it out, but few really know how it works. Knowing how it works helps us take better care of this magic component which can save us thousands of dollars over the life of our vehicles. The Catalytic converter sits in the exhaust stream of the engine as close to the engine as possible to utilize the exhaust heat to convert harmful gasses into inert gasses. Every gasoline engine makes byproducts of internal combustion; the catalytic converter is probably the biggest piece of the emissions reduction puzzle to reduce those emissions. In a perfect world if we could obtain perfect combustion only water and carbon dioxide would come out the tailpipe. That is not currently possible so let’s take a closer look at our friend the catalytic converter.

The catalytic converter is a chamber with a honeycomb center (substrate) that all exhaust must travel through to convert harmful gasses to much fewer harmful gases. The substrate is made of a combination of precious metals that act upon each other and heat to reduce overall emissions. The catalytic converter is literally creating a chemical reaction to rearrange molecules to form clearer air!

In order to do this the exhaust must touch as much of this metal substrate as possible. When the converter becomes coated with oil or carbon soot; the efficiency drops dramatically! We all know air cooled Porsches can let out a puff smoke on startup; and each time that happens a little oil gets deposited on the converter. These cars also tend to run richer than normal on cold start which builds up carbon soot in the exhaust. So, what do we do to clean these deposits off the converter to maintain converter efficiency?

Fortunately, the world of chemistry had devised a solution to keep the inside of the converter clean and efficiency high. There are several catalytic converter cleaners on the market that you just pour in your fuel tank and drive; I have listed three below. I have listed the three in order of cost and effectiveness, strongest to maintenance concentration. The first cleaner is really for when you are about to replace the converter and are looking for that final Hail Mary pass! The other two are used regularly to keep the converter contaminants under control. I have the most experience with Oxycat and have seen many a miracle I would not have believed if I hadn’t run before and after tests myself. All of these cleaners can easily be found at Amazon and other online retailers.

- Cataclean 120007 Complete Engine, Fuel and Exhaust System Cleaner (~$26)

- Liqui Moly 8931 Catalytic-System Cleaner (~$20)

- UTOPROFI OXICAT Oxygen Sensor & Catalytic Converter Cleaner # 47155 (~$16)

The key to these cleaners is to use them properly; so here are some pointers not even all the manufacturers point out. Add the cleaner with a fresh tank of high-quality fuel. I like to reduce the concentration about 25% so if it says it treats 20 gallons treat 15. Once you put in the cleaner, drive the car on the freeway for the longest time possible. You need to get the car up to temperature and maintain that temperature to maintain the cleaning process. Think of it as a self-cleaning oven that heats to 800°f and turns everything to ash. If your heat it to 800°f for 3 minutes, you are not going to turn anything to ash, just burn a lot of gas. So that is why we need to go for a good drive. We also don’t want to leave this mixture in the car for extended periods of time.

So, here’s a check list for you.

- Add a can of cleaner with fresh gas on top.

- Drive the car continuously at least 30 minutes with no/minimal idling.

- Driving the car for several hours is best like on a trip.

- Idling and full throttle are your enemies; don’t do them.

- Don’t wait until your car won’t pass a smog test, use The Liqui Moly or Oxycat at every oil change.

Steve G’s Smog Tips:

I use a can of oxycat in my 993 every annual oil service.

Catalytic converters and how they work – (2-way and 3-way)

Catalytic converters are a very complex box containing chemical reactions caused by heat and chemical conditions. I am not going to get into too much chemistry because I will just confuse myself and everyone else along the way. I will add a nice cutaway picture to help you see what we are talking about through. (See below)

Broken down we need extra oxygen molecules to stop hanging out with the bad guys in red and go over to the good guys in green. This literally changes bad gasses into good gasses just because of where the oxygen is hanging out, and some other chemicals sure…

Hydrocarbons + Carbon Monoxide + Nitrogen oxide (convert to become) H2O + Carbon Dioxide + Nitrogen

A 2-way cat needs the extra oxygen provided by the (AIS) air pump.

A 3-way cat makes its own extra oxygen in the first part of the cat and delivers it to the second part of the cat!

And don’t forget to read about catalytic converter care above!

Catalytic converter testing

Did you read the section above about how catalytic converters work? Well then, do it now!

Now that you have an idea about how catalytic converters work let’s look at how we can test them. We learned above that the converter changes the gases and oxygen levels before and after the catalytic converter. The engine computer uses the oxygen sensor readout to determine the efficiency of the catalytic converter and we can do the same thing. To do this with a non OBD-II car we just use a 5-gas analyzer before and after the catalytic converter and see the difference in gas readings before the converter and at the tailpipe.

If you don’t have a 5-gas analyzer you can use in air fuel ratio gauge before and after the converter but that is a lot more work as you need to install sensor ports.

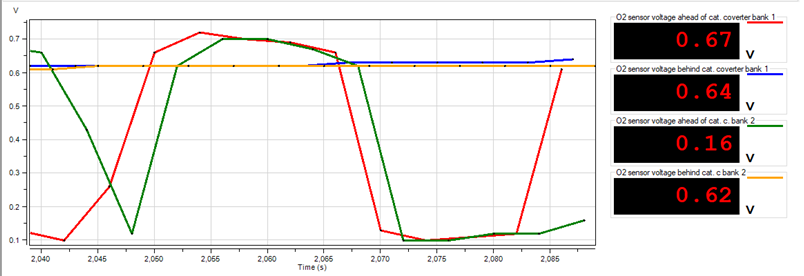

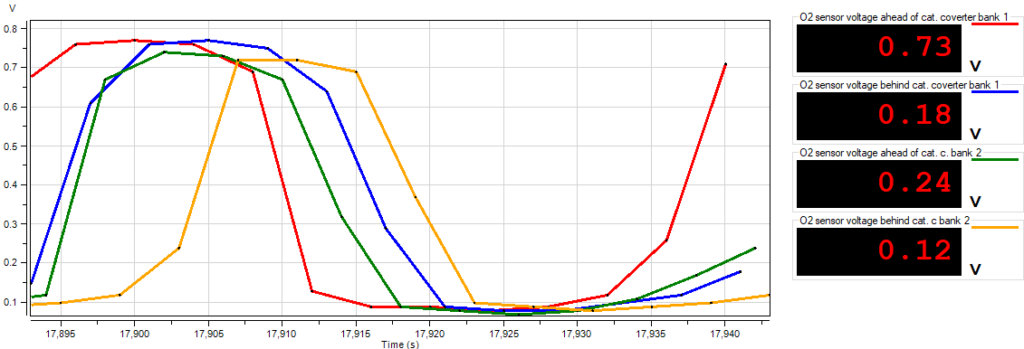

To do this in an OBD-II car we simply use the oxygen sensors that are in place and hook up to the engine computer to read the oxygen sensor voltage readout.

The graph readings below are from a diametric tester which is probably the easiest diagnostic tester to use for your Porsche with very easy to understand graphing. These are screenshots of active video voltage playback for simplicity. The voltage on the oxygen sensors before the catalytic converters will be oscillating between 200-800mv while the sensor behind the converter will be steady at around 600-700mv.

If the voltage at the rear sensor is mimicking the front sensor we have a bad catalytic converter or one that is not up to temperature.

NOx – What is it and where does it come from?

NOx is shorthand for oxides of Nitrogen. (Nitrogen Oxide and Nitrogen Dioxide) They are largely responsible for the formation of smog and acid rain. It’s serious stuff and we want to reduce it as much as possible. NOx is created in the internal combustion engine by excessive heat and pressure. Lean fuel mixture conditions and cylinder pressure increase NOx; richer mixtures and lighter load decrease it. Also, higher cylinder head temperatures like are seen in air cooled engines increase NOx, which is why air cooled engines had to be phased out.

Steve G’s Smog Tips:

The biggest cause of excessive NOx on non-computer-controlled ignition systems (Before 1984 usually) is worn ignition distributers advancing to quickly. Because the ignition timing is correct at idle doesn’t mean it is correct at 2000 RPM where the test is happening.

The second biggest cause of NOx on these cars when timing is correct is a bad oxygen sensor that is biased to the lean side and causes and overall lean fuel mixture. Check out oxygen sensor testing below.

Testing oxygen sensors

Oxygen sensor testing is widely misunderstood so let’s just break it down for you. There are different types of oxygen sensors and sub types but for our conversation we are going to stick to the number of wires. This will define what generation they are, how they work and don’t work and how they need to be tested.

An oxygen sensor is like a solar panel but different and opposite. A solar panel is exposed to sunlight and produces voltage. An oxygen sensor is exposed to exhaust and produces voltage relative to the oxygen content of the exhaust.

In other words, if the oxygen content is low, it produces a high voltage (0.90 Volts – Rich mixture) and if the oxygen content is high, it produces a low voltage (0.10 Volts – Lean mixture). But what an oxygen sensor needs more than anything is heat; about 600°f! At an idle or during warm up the exhaust can’t provide enough heat to activate the sensor. So, manufacturers added more wires, with you guessed it HEATERS!

Now that we got that out of the way; let’s do some testing!

Single black wire – (80-83):

This single black wire sensor is not heated and has no dedicated ground wire; it grounds through the housing and rusty exhaust system! It doesn’t work great but its super easy to test and they had to start somewhere!

Hook up a DVMM (Digital Volt Multi-Meter) to the connected single wire connecter. Start the car cold and you should see a steady 450mv from the control unit. Raise the engine speed to about 2000-2500 RPM and watch the voltage. It should start to cycle below and then above the 450mv starting point. After 3-4 minutes it should be reading 150-850mv roughly and cycling low to high every second, so 60 times in a minute. Get your stopwatch out on your phone and count them.

A new sensor will cycle as many as 80 times a minute and a good used one at 60 but below 50 and you are going to have issues. If the sensor is only cycling 40 times a minute you are wasting your time, it is probably not going to pass! The slower cycles mean the sensor is spending too much time on the lean or rich end of the scale so you will have either a C.O. failure of a NOx failure.

If you have a slower sensor at 40-50 cycles a minute and the car passes the test, you are still putting the catalytic converter at risk. A catalytic converter needs a fresh oxygens sensor to stay healthy, and that makes an oxygen sensor cheap insurance. 40,000 miles is really the limit for a single wire oxygen sensor, especially on an air-cooled car. Air-cooled cars pass more oil through the exhaust system especially on start up and warm up more slowly; all shortening the sensors life.

Three wire; one black and two white – (84-94)

Look, we got two extra white wires this time; but what do they do? The two extra white wires are power and ground for the sensor heater. They come on as soon as the key is turned on and stay on until the car turns off. This brings the sensor up to temperature much faster and keeps the sensor up to temperature while the car sits idling for extended periods. Black wire voltage testing is the same as the single wire sensor above; however, the heater is tested differently.

Use the ohmmeter on your DVMM and test the resistance between these two wires. You want to see about 10-20 Ohms resistance in this circuit. If you read an open circuit the heater is bad, no question. If it is much above 25 Ohms, the resistance is too high and the heater won’t actually be doing much heating.

Four wire; one black, one gray and two white – 95>

Now we have a gray wire to accompany our two whites and our single black wires. No big mystery here; the manufacturers just added a proprietary ground wire for the sensor to eliminate ground issues and less than ideal voltage readings. These later cars are more sensitive to sensor voltage variation and the grey wire takes care of that issue. The problem with these sensors is the connectors are very difficult to access or back probe for testing. Your best bet is to use a diagnostic tester like Durametrics, Autologic or a factory diagnostic tester. (Bosch 9288, PST2 or PST3)

Testing procedures and values are the same as the sensors above.

For cars 1996 and later see the OBD-II monitors section which will elaborate on sensors that test good and have no fault codes but are in fact actually bad!

OBD-II monitors!

OBD-II monitors are without a doubt the most troublesome aspect of Porsche smog inspection repair. So, what are OBD-II monitors? The monitors are a constantly operating system of tests that ensure the car is running properly at all times. These late model cars run so well that they can have an emissions related failure and you would never be able to tell by the way the car is running. So, this monitor checking system checks all the sensors and all the running parameters of the vehicle all the time.

The problem is the program is far too restrictive for real world driving and especially real world driving in a high-performance car like a Porsche. If the battery has been disconnected or the voltage has gone down or if the car has just been sitting too long without going through a complete drive cycle it will reset the monitors. Once the monitor has been reset there is a long and exhaustive self-test the car must complete before the monitors will pass (Clear).

But before we go there let me tell you about the deep dark secret concerning OBD-II monitors that I have personally never seen in print but have discovered over years of research and diagnostics. Using a diagnostic tester check oxygen sensor resistance on a car at full operating temperature. A newer oxygen sensor will read zero ohms resistance and the closer to 50 ohms it gets the harder it will be to engage the OBD-II monitor sequence test; especially the catalytic converter efficiency test. From 50-100 ohms the likelihood of lock out doubles and at 150 ohms or better the chance of running a timely monitor passing sequence is all but impossible. So, if you are having trouble getting the monitor test to go especially the catalytic converter efficiency test, check sensor resistance and replace the sensors that are near or above 50 ohms; and you will thank me!

Now for running the monitor test on those difficult cars! Porsche actually has a huge manual dedicated to OBD-II systems and diagnostics. It is involved so I digested everything in it and have produced two single page documents with the distilled results. One is a very detailed plan that you must have a diagnostic tester to watch RPM, AFM load, injection duration and time to give the car the exact condition it wants. I wrote this specifically for 993s back in the early 2000’s; but it applies specifically to 996/997/986/987 cars as well. Cars built past 2010 are less problematic.

The other is the very simplified version that will usually work after several attempts on very low trafficked roads late at night. It can be completed by anyone without any special equipment.

The detailed version monitor clearing procedure:

993 Monitor Test Drive Sequence.PDF

The easy monitor clearing procedure for Porsche and BMW that anyone can do:

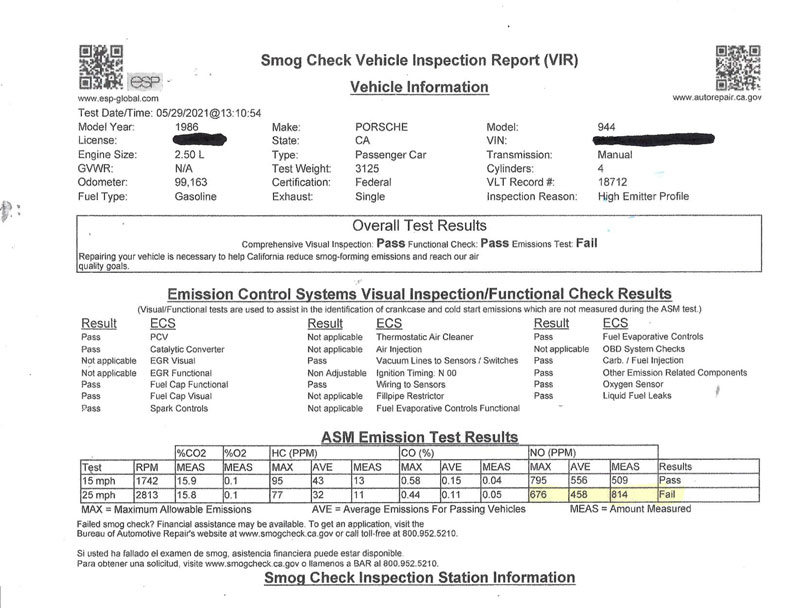

Understanding your VIR and 5-Gas reading diagnosis

Understanding your failed VIR (Vehicle Inspection Report) can be difficult and may seem like a foreign language. I have added this document below from the SmogTechInstitute.com which simply lays out the diagnosis procedure. Read the entire document and you will be smarter than 97% of people with a failed VIR!