Tires and suspension set up and adjustments

Tire construction and heat cycles:

Tire structure is steel and nylon that gives the tire the shape.

The outside of the tire is synthetic rubber that heats up with friction and gives us that much needed stick!

The greatest friction is from breaking, the second greatest is from cornering and the third greatest is from acceleration.

As the tire heats up and then cools down it experiences a heat cycle.

Cars that are double stinted do not cool down as much so those tires will experience longer usable laps or milage.

10 laps come in and take 10 laps will usually act like 15 heat cycles.

This heating up of the tires makes the tire flex and move at a predictable rate and pattern.

As the heat cycles increase the structure becomes less predictable and less elastic.

This makes a tire lose traction seemingly without warning.

This tire hardness is measured with a tire durometer and must be done on a warm tire preferably over 140°f.

While sliding and drifting are great fun, they are the worst form of heat friction as it overheats the outer layer of rubber and not the core of the tire.

This will cut your usable heat cycles in half. Save this fun for a set of tires on their last run session when they are just going in the trash.

The scrubbed in tire (your best friend):

A new tire with cool Hoosier stickers on it will not give you its fastest laps.

The fastest laps of a tire are after it has been scrubbed in and put up.

This must be done a minimum of 24 hours before use and a week before is optimum.

To do this take your new tires with the stickers removed out and warm them up very slowly with no sliding or drifting.

Inflate the tires 3-4 psi higher than normal.

The fastest of these laps should be run at about 70% so no abuse happens.

The key to this session is slow controlled temperature management.

Two warm up laps, two medium speed laps and two 70-80% fast laps with no cool down laps.

When the session is done get in quick and get the tires up off the ground ASAP so they can cool evenly.

The section of tire that is on the ground will cool off much slower that the section in the air.

This will result in different molecular structure around the tire.

I usually scrub tires in in the second session of the first day of practice.

Scrubbing a set of tires in the last session of the day for the next day morning sessions has negligible benefits.

Heat cycles and cookies.

Heat cycles should be marked on the tire sidewall with a tire crayon to give you an idea of how far along is the tire life.

Remember a tire is done when it is excessively worn or no longer sticks.

Don’t waste laps because a dead tire still has tread left.

Heat cycles are like fresh baked cookies that Grandma made for you.

Today’s cookies and last week’s cookies will look the same but one is soft and delicious and one will break your tooth!

Tire softness and heat cycles are not the black magic everyone thinks it is – just use a tire durometer.

A tire durometer is a gauge with a needle that pokes into the tire’s surface.

The farther the needle sinks into the tire the lower the durometer number and the softer the rubber.

All tires are different, but rubber hardness is measured in a 0-100 Shore-A scale.

200 tread wear tires will usually measure 50 on a new hot tire and 70 on a dead heat cycled out tire.

Measure hardness at three places across the face like tire temperature.

Tire problems…

Blistering happens when a tire is hotter inside than outside and an air pocket expands under the tires surface.

This literally appears like a burn blister on your skin.

Blistering does not happen as much as it used to with the advancement in moder tire technology and construction.

A blistered tire is damaged and will come apart in short order, so replace this tire.

Graining happens when the outer surface of a tire heats up much faster than the core or the tire.

(Going out to fast and hard and not letting the tire heat up uniformly).

This outer layer becomes very soft and rolls up like pencil eraser pieces.

These pieces stick back onto the very hot tire and create a grained surface.

This grained surface is bad because the raised pieces keep the surface of the tire from contacting the surface of the road.

Graining is usually caused by the driver, not the car or set-up.

Flat spotting a tire:

A tire becomes flat spotted when the brake effort overpowers the traction of the tire.

The flat section of the tire becomes overheated and hard and will find the flat track very easily next time.

The loss of rubber also means you are closer to cording the tire.

While flat spotting a tire usually only happens of non-ABS car is can occur on ABS equipped cars as well.

Breaking over an excessively rough area or spinning out and sliding sideways can cause flat spotting.

Tire Specifications…

Treadwear (UTQG) Ratings:

Maybe you’ve heard of the Uniform Tire Quality Grade (UTQG) Standards or Treadwear ratings to us regular folks.

It’s important to note the DOT doesn’t conduct the tests for UTQG grading, it is subjective, and market driven.

The tests are performed by the tire manufacturers (or a 3rd-party testing company) and reported to the DOT.

Generally, the lower the number the stickier the tire and the faster it will wear out.

So, let’s dive into what each Grade.

40 DOT: legal slicks (Hoosier)

100 TW: Not as sticky as 200TW but have odd sizes. (Toyo R888r and RA-1)

200 TW: cheater SCCA tires – These are hands down the most stick and durability for the money.

These tires also have greatest variation in tire performance and application (See 200TW explained – below)

240 TW: These less expensive summer sport tires are a great sport sedan or casual track day option.

(Michelin Pilot Sport Cup 2 Connect (240) is a serious PCA Street Stock tire.

300 – Very high performance (for a 300TW) with high durability and heat resistance –

(Michelin Pilot Sport 4S) Great for hot lapping your heavy track car and driving home with no worries.

200 TW explained:

200 treadwear tires are a SCCA showroom stock class of tire and why our rules say 201 and above.

They are a specific class of tires that have little to do with the actual treadwear.

Here is a rundown on why you would pick each of these popular 200TW tires.

These are my opinion of tires I have personally run, so not all brands are listed.

Size availability is also a huge factor for these tires.

(*Price favorite)

Fast, sticky and short lived as they do not like too much heat.

These are really AX and timed run tires.

Also, the most expensive.

BFGoodrich g-Force Rival S 1.5

Fast practice laps that are super consistent and durable.

Falken Azenis RT660 (Cheap RE71-R) *

Kumho ECSTA V730 (Extreme heat resistance and good for camber limited set ups). *

Lots of cheap practice laps, but not as fast when pushed.

DUNLOP DIREZZA ZIII (Lasts forever)

Here is what Grassroots motorsports says about all the available 200 TW tires

https://grassrootsmotorsports.com/articles/track-tire-buyers-guide/

Tire pressure basics and fine tuning:

Road race/Track Applications for Hoosier R7

| VEHICLE SIZE | RECOMMENDED HOT PRESSURE | COLD PRESSURE |

| 1800-2200 LBS. | 32-34+ | 26-28 |

| 2200-2600 LBS. | 34-36+ | 26-28 |

| 2600-3000 LBS. | 36-40+ | 26-30 |

| OVER 3000 LBS. | 40-42+ | 30-34 |

Road race/Track Applications for average 200 TW tires.

| VEHICLE SIZE | RECOMMENDED HOT PRESSURE | COLD PRESSURE |

| 1800-2200 LBS. | 28-30+ | 26-28 |

| 2200-2600 LBS. | 30-34+ | 26-28 |

| 2600-3000 LBS. | 34-36 | 26-30 |

| OVER 3000 LBS. | 36-40+ | 30-34 |

Tire temperatures and the story they tell.

Always check tire temperature with a probe type meter, not a surface pyrometer.

You need to check the tire core temperature, not the surface temperature.

We want tire temperature to be linear from the hottest temperature on the inside to the lowest temperature on the outside.

Ideally, we want a 5°f difference inside, center, outside and anything over a 20°f total difference needs correction.

| Tire Pressure | Left | Right | Tire Pressure | |||||||

| Initial | Post | Outer | Mid | Inner | Inner | Mid | Outer | Initial | Post | |

| Front | 25 | 34 | 183 | 185 | 187 | 178 | 195 | 188 | 25 | 37 |

| Rear | 25 | 33 | 172 | 175 | 178 | 185 | 179 | 175 | 25 | 35 |

Any car with higher outside tire temperature and -3.5° camber needs suspension correction to make the car flatter.

Ideally stiffer springs or stiffer sway bars.

Fine tuning tire pressures is done by monitoring tire temperature across the face of the tire.

The right front tire is over pressured, but all other tires are ideal.

(See red right front temperature settings above)

See the bottom of this article for tire temperature sheet documents.

A nice excel sheet for computer types and an easier pdf for those of you who like a clip board and pen!

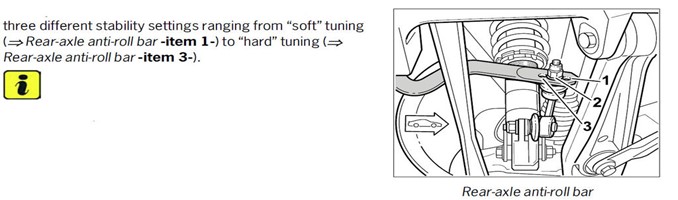

Sway bar adjustment (Actually anti-sway bar adjustment):

The goal is to have the stiffest setting possible with the best handling and front to rear balance.

A stiffer setting will make the car ride flatter and decrease chassis roll and outside tire wear.

The flatter the car rides, the more tire will be flat against the road and the more overall grip you will have.

If the car is bouncing through a turn or hopping a looser setting may help.

Adjustments:

The closer the drop link is to the end of the adjusting arm; the softer the sway bar is.

Conversely, the farther the drop link is from the end of the adjusting arm; the stiffer the sway bar is.

The goal is to first achieve perfect front to rear balance.

No unwanted oversteer of understeer, just what can be induced by throttle inputs.

Ideally you want to loosen the adjustment first as that adds stick as opposed to taking stick away.

After you have achieved this balance start making the sway bars evenly stiffer front and rear.

When making adjustments, it is usually agreed upon that you move left and right drop links evenly.

However, when making small adjustments you can move one side as much as an inch different to get a “Half Change”.

Glossary:

Drop link: Part between suspension and sway bar that provides adjustment.

Hard/stiff/firm setting = less stick

Softer/looser setting = more stick

Numbered sway bar holes or positions are usually (1 soft) and the number increases as stiffness increases as shown below.

- Soft

- Med

- Stiff

(Rear adjustment of a Porsche Boxster pictured).

Single adjustable shock adjustment:

Adjustable shock dampening can get extremely complicated and is not for the amateur driver.

The saying with adjustable shocks is that there is one perfect set up and 99 wrong ones.

Good luck.

Start with shock settings at 50% range and start making minor adjustments and record changes and results.

Bilstein-

NOTE: on the PSS9 kits the knob adjustments are reversed from PSS10. Setting 9 (CW) is the softest and setting 1 (CCW) is the firmest.

NOTE: on the PSS10 kits the knob adjustments are reversed from PSS9. Setting 1 (CCW) is the softest and setting 10 (CW) is the firmest.

JRZ RS-1

Adjustment clockwise makes the damping softer, counterclockwise makes the damping harder.

Tire temperature sheets to download and print!